This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

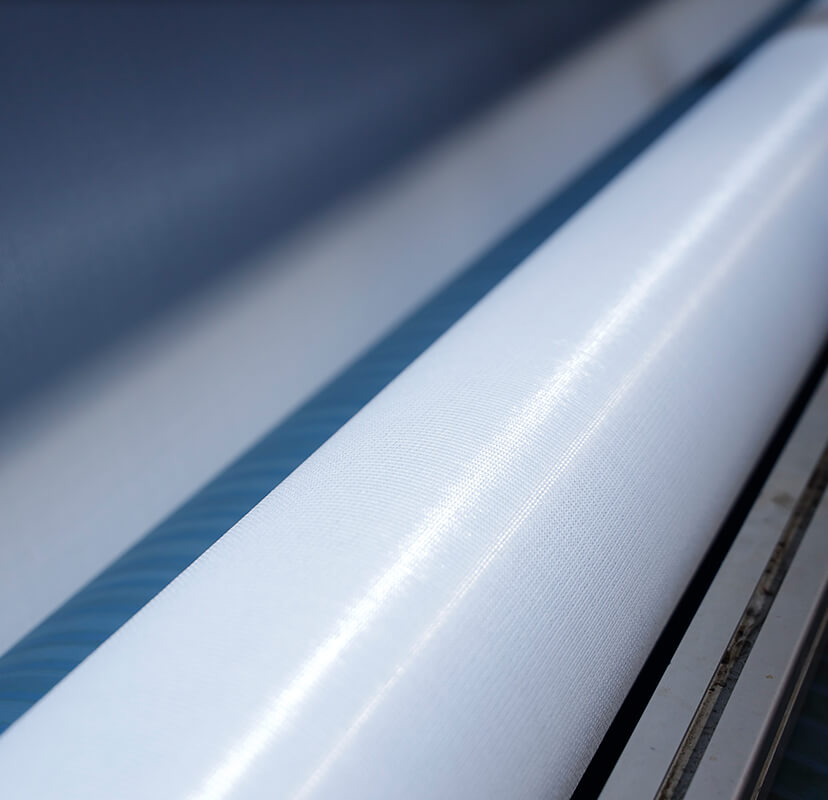

StrataTex HSR™

High-Grade Polyester Geotextile for Soil Reinforcement

Overview of StrataTex HSR™

Adaptable Geotextile for Future Soil Strength using StrataTex HSR™

Presenting StrataTex HSR™, our latest innovation in high-performance geotextiles; a product tailored to the demands of soil reinforcement and advanced civil engineering projects. Constructed from elite-grade polyester yarn, StrataTex HSR™ offers a perfect blend of high tenacity and low creep attributes, meticulously knit into an unwavering network for superior durability and strength.

What truly sets StrataTex HSR™ apart from traditional geotextiles is its astounding array of industry-leading features. StrataTex HSR™ exhibits remarkably lower elongation compared to its competitors, presenting a resilient fabric resistant to deformation, thereby ensuring long-term structural integrity. Furthermore, our product excels in the areas of stress-strain values, significantly enhancing your project’s durability and lifespan.

The high permeability performance of StrataTex HSR™ ensures optimal fluid management, thus reducing the risks associated with water build-up and erosion. Its innovative design helps to prevent any potential damage to structures, offering a safeguard that ensures the long-term stability and sustainability of your project.

With adaptability in mind, StrataTex HSR™ is available in extensive widths, up to an impressive 5.8 meters. In addition, it offers customizable lengths to suit a wide range of project requirements, guaranteeing efficient and cost-effective usage. This level of flexibility is what makes StrataTex HSR™ a game-changer in the industry, designed to cater to the specific needs of your individual projects.

Key advantages of StrataTex HSR™

What makes our geotextile unique?

- Certified and Accredited Excellence: Whether you're undertaking the reinforcement of base layers or developing paved roads, the StrataTex HSR™ has been rigorously tested in GAI-LAP accredited labs and holds both CE and ISO certifications. This confirms its unwavering commitment to offering quality and reliability in all geotextile applications.

- Resource Optimization: StrataTex HSR™, with its wider widths and customizable lengths, reduces overlaps and wastage, enhancing efficiency in every project, from the construction of unpaved roads to the implementation of complex load transfer tasks.

- Incredible Tensile Strength: Offering a wide range of ultimate tensile strengths, from 50 kN/m to a remarkable 800 kN/m, StrataTex HSR™ is the go-to solution for strengthening soil structures, basal reinforcement, and ensuring the durability of paved and unpaved roads.

- Low Elongation, Full Strength: StrataTex HSR™ delivers its full tensile strength at low elongation, which is essential for all applications including soil reinforcement, load transfer, and basal reinforcement. This ensures maximum durability and resilience for your geotechnical projects.

- Superior Permeability: StrataTex HSR™ exhibits high water flow capacity due to its excellent permeability, which is particularly beneficial when improving the stability of unpaved roads or reinforcing the soil. This helps to minimize the risk of water-related damage and enhance the structural longevity.

- Unparalleled Stability: The unique knitting technique used in StrataTex HSR™ enhances its stability, making it a preferred choice for geotextile applications that demand robustness, such as load transfer and basal reinforcement. This ensures safer handling and seamless operational experience.

What impact does our StrataTex HSR™ create?

Environmental

Time-efficient

Economical

Manufacturing Process of StrataTex HSR™

How is our geotextile manufactured?

StrataTex HSR™ is manufactured in the state-of-the-art manufacturing plant located in India.

The manufacturing process involves 2 phases:

Beaming

A predetermined number of yarn ends are pulled from a creel and are wound onto a large cylindrical beam. We have fully automated, highly sophisticated beaming machinery, which ensures uniformity in yarn tension and take-up and unwinding stability.

Knitting

Using state-of-the-art knitting machines, high tenacity Polyester yarn is precision-knitted into a dimensionally stable network of apertures.

Beaming

Beaming

A predetermined number of yarn ends are pulled from a creel and are wound onto a large cylindrical beam. We have fully automated, highly sophisticated beaming machinery, which ensures uniformity in yarn tension and take-up and unwinding stability.

Knitting

Using state-of-the-art knitting machines, high tenacity Polyester yarn is precision-knitted into a dimensionally stable network of apertures.

Applications of StrataTex HSR™

Where can our geotextile be used?

We guide engineers, contractors, and owners to use StrataTex HSR™ to achieve cost effective, sustainable, and reliable solutions for various site development challenges.

Basal reinforcement for embankments on soft soil

Embankments over soft soil need basal stabilization during construction and until the foundation soil gains sufficient shear strength due to consolidation. Basal reinforcement distributes the load over a wider area and provides resistance against shear failure due to tensile strength improving the safety against bearing and shear failure of the embankment. Here, StrataTex HSR™ caters to two applications: (1) Separation (2) Reinforcement. A separator is required in the basal reinforcement system consisting of geosynthetic reinforcement and granular fill, to avoid mixing and loss of granular fill within the soft layer. StrataTex HSR™ separates and reinforces simultaneously, eliminating the need for an additional layer and reducing the cost and installation time.

Paved and unpaved roads

Pavements that are to be constructed on expansive or slushy soils with soft clay as subgrade, need a strong long-lasting separator above subgrade to ensure performance over the service life of the pavement. Using StrataTex HSR™ on subgrade not only provides the separation required but also improves the modulus of the granular layer above subgrade owing to its tensile modulus. StrataTex HSR™, when placed above subgrade, improves the modulus or layer coefficient of the granular material above by reinforcing that layer based on friction, interaction, and tensile strength properties of StrataTex HSR™. StrataTex HSR™ possesses excellent permeability and strength compared to nonwoven geotextiles which cater to a higher flow of water, ensuring serviceability performance of the pavement.

Load transfer platform for piled embankments

Embankments constructed over piles, on soft ground, need a load transfer platform with basal reinforcement spanning across pile caps to ensure the transfer of embankment loads onto the piles. Using StrataTex HSR™ ensures separation and tensile strength provision to the load transfer platform system catering to both separation and reinforcement in one geosynthetic layer. It ensures smooth load transfer from the embankment to the pile caps providing the required serviceability to the embankment without excessive deformations in the region between pile cap spacing. With proper design of basal reinforcement using StrataTex HSR™, the pile cap size and pile spacing design can be optimized to ensure economy along with safety. These load transfer platforms are designed in line with international guidelines such as British Standards and FHWA (Federal Highway Administration) in the USA.

Quality Assurance of StrataTex HSR™

How long does our geotextile last?

Many design engineers face challenges finding geosynthetic reinforcements that meet quality standards. The long-term performance of a geotextile is dependent on several factors such as raw materials used, the manufacturing process adopted, the designs, and the end application.

Since geotextiles are used for critical designs, it is essential to have a clear understanding of the above factors. To meet those standards, StrataTex HSR™ undergoes exhaustive testing at internationally reputed laboratories to define all of the above factors.

What are the different stages of testing for StrataTex HSR™?

QC testing

Construction damage testing

Pull-out testing

UV protection

DOWNLOADS

Looking for a little more than light reading?

CONSULTATION

Is there something more you would like to know about StrataTex HSR™?

Strata not only provides geotechnical products, but our team of 200+ engineers can help you with your turnkey project by supplying you with technical know-how and support as to how our products can help you finish your projects in time while keeping costs down.

Send us your queries and we will get back to you with our expertise.