Erosion Control

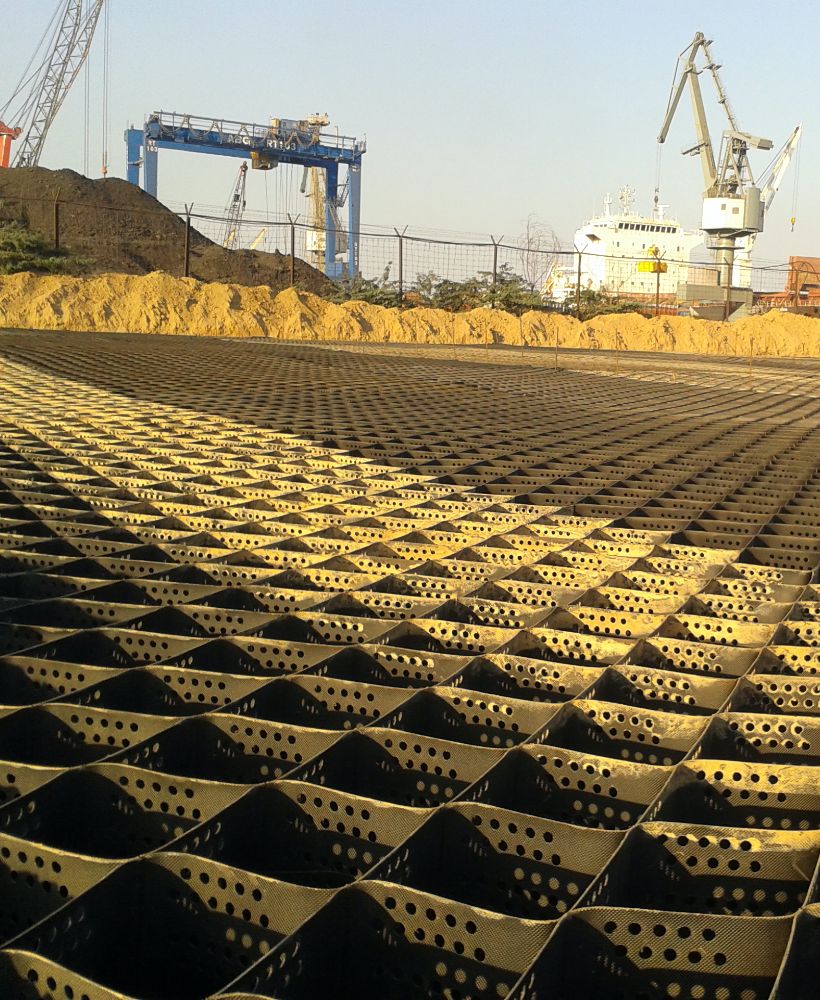

The confinement action of StrataWeb® reduces erosion on slopes caused by rain, wind, and other factors. StrataWeb® protection system can be engineered to suit slope conditions, from very steep 60-degree slopes to very gradual 27 degrees slopes. It provides a cost-effective and long-lasting solution. After the slope is dressed and compacted, StrataWeb® can be expanded and installed rapidly using Strata connectors and anchor systems.

Multiple infill options are available, including soil, concrete, and gravel. StrataWeb® proves to be more economical compared to stone pitching and paver tiles and is substantially longer lasting as compared to jute/coir mats.

StrataWeb® can be purchased along with the anchoring systems – StrataLock, StrataCord, and StrataFast. These are the connectors that bind the geocell panels together.