This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

What factors affect pavement life?

Pavements form an integral component of our transportation infrastructure. Depending on the type, while pavements can be made of different materials, cracks appear on paved asphalt roads or paved concrete roads typically. However, several factors affect the performance and lifespan of a pavement. This makes pavement cracking a significant concern for constructors.

The core source of this is the pavement structure itself which is affected by the load it’s subjected to, temperature changes, or also destabilisation of the structure overall. As a result, paved roads end up with reduced durability, increased maintenance costs, and safety hazards. Understanding the various types of cracking and what exactly causes them is essential in order to implement effective mitigation strategies. In this blog, we focus in detail on the factors that affect pavement life. From different types of cracking, their causes, and effective prevention and maintenance strategies –we go into depth of the subject.

Types of pavement cracking

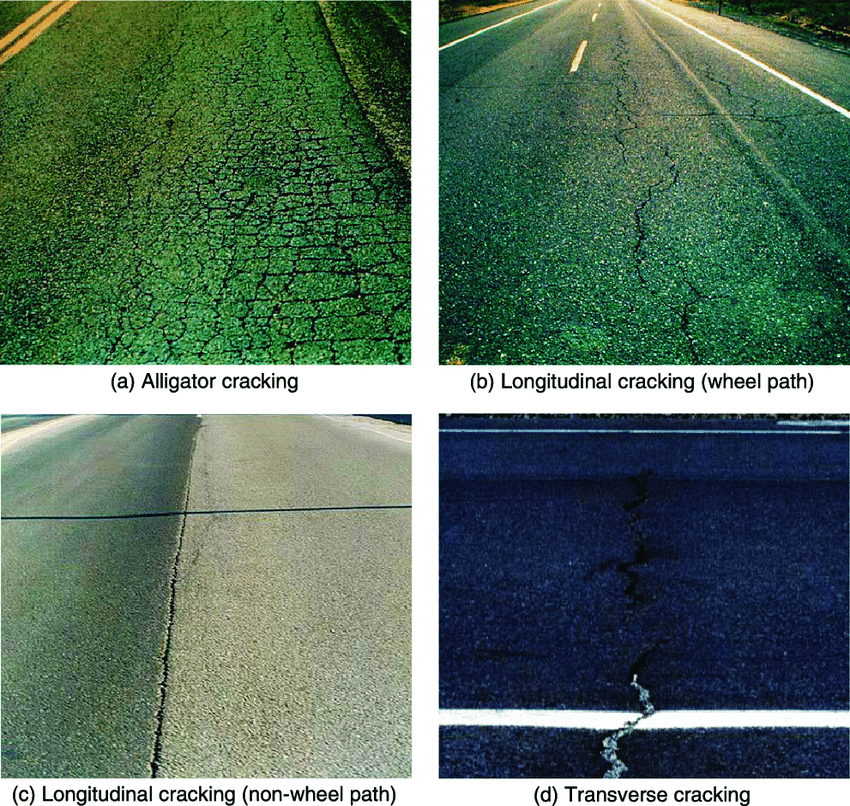

Pavement cracking is defined as distress on the surface of the pavement, which can take on many forms, based on the material used. There are many types of cracks across different paved and unpaved roads. Pavement cracking can be categorised into three forms:

- Top-down cracking or also known as surface-initiated cracking

- Bottom-up cracking or also known as bottom-up fatigue cracking

- Combination cracking

Bottom up cracking is associated with heavy traffic loads that affect the subgrade and cause a domino effect of issues while top down cracking is largely associated with climatic conditions such as acute temperature variations causing the cracks to propagate downwards. Here, we discuss in detail the top down cracking types.

Asphalt cracking

This type of cracking is most commonly found. It has a series of interconnected cracks. It is usually caused by repeated traffic loads and is often worsened by construction-centred issues such as inadequate pavement thickness or poor drainage. To fix this type of cracking, remove the cracked pavement area, dig out and replace the area of the poor subgrade and improve the drainage of that area—patch over the repaired subgrade.

Crocodile cracking

Crocodile or alligator cracking is a form of asphalt fatigue cracking. This is a form of distress having a series of interconnected cracks. These cracks resemble the pattern of a crocodile’s skin. It is typically caused by structural failures within the pavement layers, i.e distressed caused by repeated traffic loading. The other symptoms leading to this cracking are inadequate structural support, or ageing of the pavement material. Sometimes, it’s also interchangeably referred to as fatigue cracking as a way of identifying the cause of the crack. Inherently, fatigue cracking points to the underlying mechanism of failure, which is fatigue caused by repeated loading on the pavement, whereas crocodile cracking refers to the visible cracking pattern. To fix alligator cracking, you will need to remove the damaged section, compact the base, and then patch it up.

Longitudinal cracking

Longitudinal cracks can either be fatigue cracks or top-down types of cracks. These are cracks that run parallel to the pavement’s centerline or lay down direction. These cracks often result from poor joint construction, reflective cracking from underlying layers, or continuous thermal contraction and expansion. The best repair method to repair cracks in concrete pavement is through the use of a good quality epoxy.

Transverse cracking

These perpendicular cracks extend across the pavement at approximately right angles to the pavement’s centre line or direction of laydown. We can see these often resulting from low-temperature cracking, inadequate pavement thickness, or structural fatigue. The Flush-Fill-Crack-Seal method wherein you flush a crack with a sealing material, fill it and seal it works to fix this type of a crack.

Block cracking

This type of cracking forms a series of interconnected rectangular patterns. It is usually caused by shrinkage of the asphalt concrete or the ageing of the pavement. A stark difference in temperatures can also cause block cracking.

Effects of cracking on pavement

Pavement cracking has a number of ramifications. Right from maintenance led issues, to other broader effects, it’s a problem best avoided by proper pavement design and implementation of best-in-class construction processes. They can broadly be classified under the following heads.

Reduced structural integrity

Cracking has a very poor impact on the structural integrity of the pavement. This leads to further deterioration and safety hazards. It also makes pavements less functional and unsafe to use.

Increased maintenance costs

Pavement Cracking calls for frequent repairs and maintenance. Frequent repairs can be costly and time-consuming because a lot of manpower and materials are used.

Safety hazards

If there are too many cracks on the pavement, they can create uneven surfaces, potholes, and other hazards. These can be dangerous and can cause accidents and injuries.

Reduced aesthetics

Cracking can make a place look low and shabby. They can detract from the appearance of roadways. This adversely affects the overall aesthetic appeal of the surrounding area.

Environmental impact:

Cracking can lead to issues such as water infiltration. These can further cause a chain of issues such as erosion and environmental damage.

Causes of pavement cracking

Pavement cracking is a maintenance issue that recurs on either poorly constructed roads, or roads which are experiencing heavier than planned loads, among other reasons. To do so, it is important to first understand the root cause of it. Some of the most common causes of pavement cracking have been listed below.

Heavy traffic loads

The magnitude and frequency of traffic loads impact the lifespan of pavements significantly. When a pavement has heavier loads than planned or increased traffic volume, the appearance of pavement cracks will be accelerated. Since the subgrade tends to compact under loads –there could be a number of issues.

Climate conditions

Extreme temperature fluctuations, prolonged exposure to sunlight, and moisture infiltration weaken the asphalt binder. This weakening is a major factor leading to pavement cracking. Freeze thaw cycles are iterative and worsen the chances of cracking due to the extreme temperatures. Freeze thaw cycles are essentially when water freezes due to cold, and expands. This expansion causes the pavement material to crack, and spall. Once the ice thaws in warmer climates, the pavement contracts. This cycle causes an endless loop of damage to the pavement.

Pavement design and construction:

Faulty pavement design and construction can cause pavement cracking. Inadequate pavement thickness, poor drainage, and substandard construction practices cause premature cracking and deterioration.

Subgrade Issues

Poor subgrade preparation or inadequate support can lead to structural failure and cracking and is one of the leading causes for cracking on the pavement surface. Often, moisture intrusion, inadequate base support, or repetitive deformation of the subgrade under pressure are among the contributors to pavement cracking.

Lack of routine maintenance

Failure to conduct regular inspections, timely repairs, and preventive maintenance measures can exacerbate cracking and lead to further deterioration.

How to prevent pavement cracking

The core ingredient for a good pavement lies in the first step, i.e. pavement design. As this division of civil engineering evolves with a deeper understanding of geotechnical forces, materials that affect design positively or negatively, the need to have a good foundational start for roads is key. At Strata Geosystems, we provide services for design, manufacturing and installation to ensure a singular vision in executing some of the country’s most prestigious projects.

Pavement design

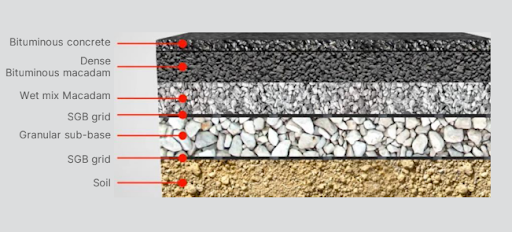

A proper pavement design is an effective way to maintain pavement to prevent cracking. These include pavement thickness and structural design to withstand anticipated traffic loads and environmental conditions. Right from understanding the load bearing capacity of different soil subgrades to understanding the ecological impact of deploying construction materials –all of these make a difference in the planning of a paved road, or asphalt road. The pavement design needed for a highway versus an access road vary and need to be considered during this process. For example, Strataweb, or our geocell [cellular confinement system] is a load support solution that is ideal for low CBR grounds with heavy loading requirements and helps save on natural resources by reducing the aggregate layers.

Good quality materials

The materials used in the pavement make a lot of difference. Inferior quality materials make the pavement more susceptible to cracking. While traditional methods for subgrade improvement have been in use, today, using geogrids, geocells, and geocomposites solve many of the common engineering challenges. Right from reducing the need for excavation to improve subgrade, to reducing the amount of backfill to other soil improvement techniques, our products at Strata Geosystems help address all of these issues. These products in turn ensure structural stability by improving load bearing capacity, rendering improved shear strength across soils, and also help minimise the impact of soil compaction under heavy loads.

Routine maintenance

The biggest benefit with use of geosynthetics is the reduced maintenance costs. While traditional construction materials mean heavy upkeep needed for proper maintenance, geosynthetics reduce this by improving structural quality. Even implementing geosynthetics in isolated stretches, layaways and regular inspections, timely repairs, and implementing preventive maintenance measures can make a lot of difference.

Effective drainage

Ensuring proper drainage systems will prevent water infiltration and erosion. This will eliminate cracking due to the weakening of the foundation by water seeping in. By using products such as geocell, which allows water to pass through easily which is a necessary feature for soil improvement in water saturated soil types. The StrataWeb, or geocell is ultrasonically welded together to create a strong, lightweight expandable panel which spreads the loads forming on top over a larger area, effectively increasing the infilled material’s modulus.

Materials to mitigate cracking

Strata Geosystems is your partner when it comes to geosynthetics products. Pavement cracking can be a major issue when it comes to the construction of heavy structures. We have a broad spectrum of products that can help in mitigating the issue. The two major players are StrataWeb® and SGB Grids.

StrataWeb® and SGB Grids help in the maintenance of pavement sections by reducing the requirement of expensive quarried materials in the base and sub-base layers while providing longevity.

SGB Grids: biaxial polyester geogrids

SGB, also known as StrataGrid Biaxial grids are made of polyester or PET and are flexible, high-performance geogrid. Ideal for soil reinforcement, our products are designed for easy installation. Some of its key features include:

- 5.0 m width for wide coverage of surface area

- Strength of up to 150 kN

- High molecular weight (>25000 g/ mol)

- SGB Grids have high load-bearing capacity which is a major factor in mitigating pavement cracking

StrataWeb® and SGB Grids help in the maintenance of pavement sections by reducing the requirement of expensive quarried materials in the base and sub-base layers while providing longevity.

StrataWeb®: geocells

Our product, Strataweb, i.e. geocells are Cellular Confinement Systems (CCS) most commonly used in a slope protection system offering low-cost, high-performance solutions for slope erosion challenges. These three-dimensional cellular confinement systems are manufactured from textured and perforated high-density polyethylene (HDPE) strips, and help with the movement of water, confining soil, and improving weak soil quality. What makes our geocells valuable for your civil engineering requirements is:

- Cost-effective and fast installation

- Easy transportation due to the flexible & collapsible material

- Steep slope up to 60 degrees

- Multiple infill options – soil, concrete, aggregates

- In the case of slope installation, it allows vegetation to grow

Factors that affect pavement life, particularly cracking, are essential for ensuring the longevity and performance of our roadways. Addressing different types of cracking and their causes helps in adopting prevention and maintenance strategies. By doing so, we can enhance the durability and safety of our transportation infrastructure. Diligent planning, construction practices, and ongoing maintenance efforts can help us pave the way for smoother and more resilient road networks.