This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

What are geogrids and their uses?

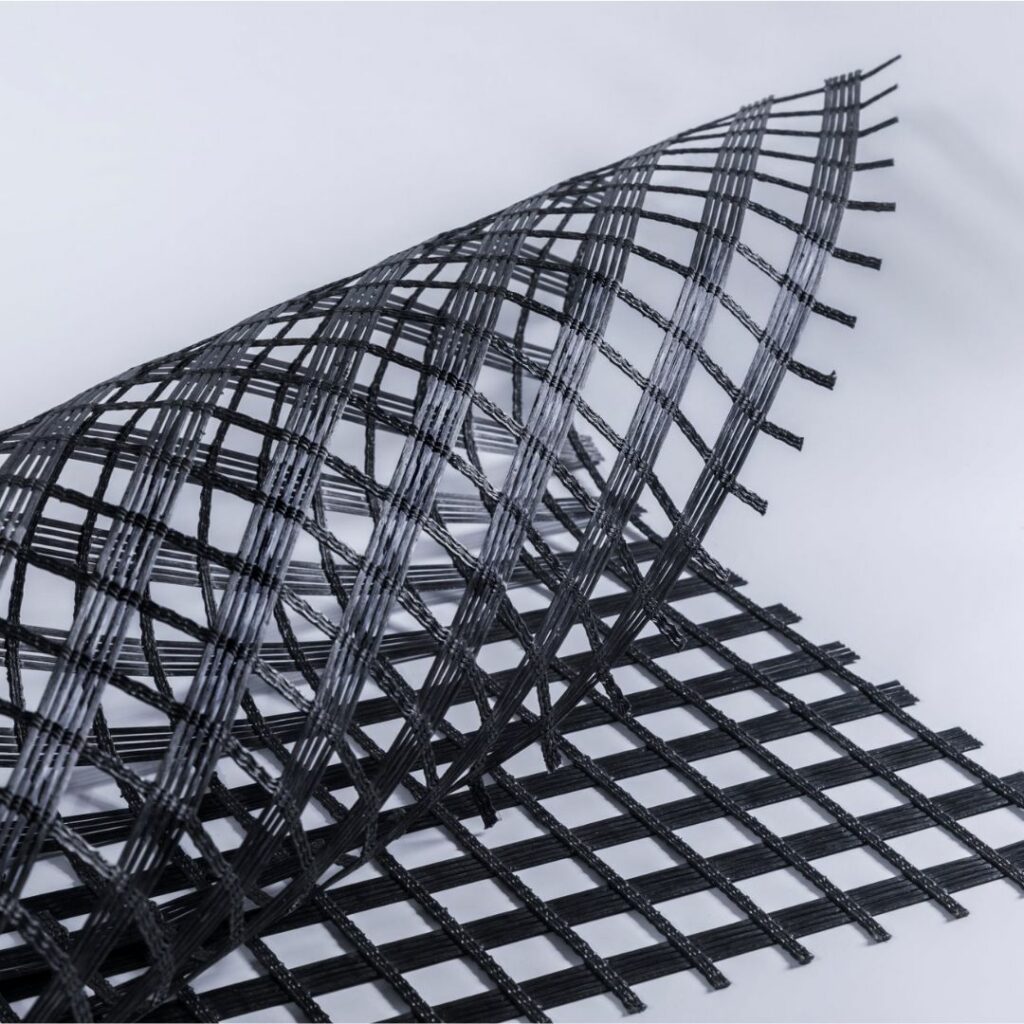

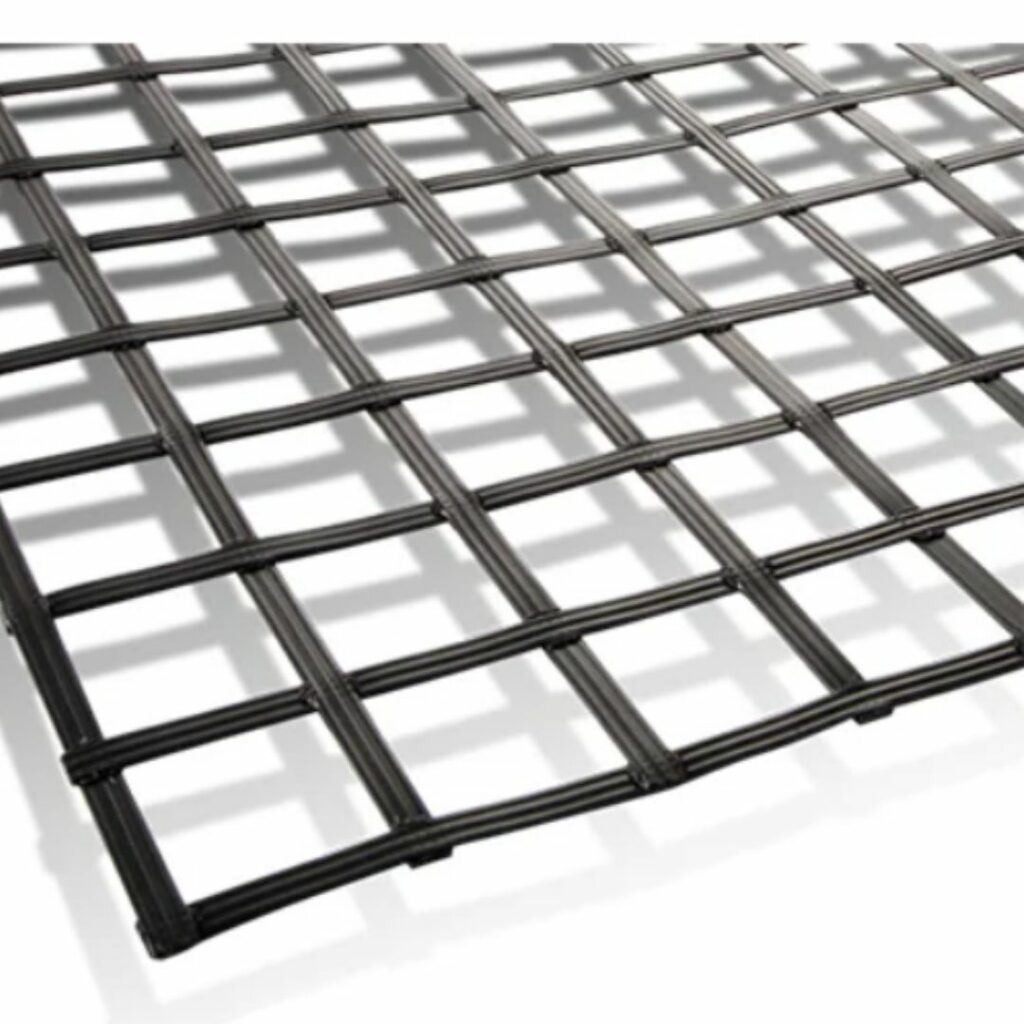

Synthetic materials called geogrids, a subclass of geosynthetics, are used in civil engineering to improve soil stability, offer reinforcement, and facilitate drainage. For certain uses, these mesh-like structures made of polymers like polyester, polypropylene, or polyethylene provide multidirectional strength and stability. When combined with the proper infill, geogrids—interconnected tensile ribs—provide reinforcement and stability by locking with the underlying soil or aggregate. Geogrids are geosynthetic materials that are essential for stabilizing surfaces on soft ground, prolonging pavement life, and minimizing road thickness without sacrificing strength. Geogrids are widely utilized in heavy load situations, agriculture, and a variety of civil engineering projects, including retaining walls, highways, slopes, embankments, and erosion control. Their remarkable tensile strength is on par with that of steel and concrete. Geogrids are essential to civil engineering because of their capacity to increase strength and stability.

What are the different types of geogrids?

Geogrids materials are specifically designed for civil engineering needs and are available in different types. Most commonly geogrids are divided into two categories: 1. based on patterns and 2. based on manufacturing. Let’s look at them based on their patterns, how they are made, and what materials are used.

Types of geogrids based on pattern:

1. Uniaxial geogrids- Uniaxial geogrids, which are composed of polyethylene or polypropylene, have a high tensile strength in a single direction, which allows them to support heavy loads. StrataGrid™ from Strata Global and other uniaxial geogrids are widely used in embankments, retaining walls, and landfill liners constructed on unstable soil or steep slopes. It is perfect for supporting slopes and walls because of its strength in a single direction. They also minimize soil erosion by distributing loads efficiently. Because they are eco-friendly, they improve stability and safety and add to the sustainability of building projects. Uniaxial geogrids, which come in different grades, offer customised solutions for a range of infrastructure requirements. StrataGrid™uniaxial geogrid is an innovative geogrid that serves as a highly efficient soil reinforcement solution. Main features of this geogrid which makes it different from other geogrids are: StrataGrid is manufactured under stringent quality controls using specialised high tenacity polyester yarn. The HT yarn is made from PET polymer having varied characteristics:

✓ High molecular weight (>25000 g/ mol)

✓ Low CEG number less than 30

✓ Low creep

- A UV stabilised unique Polymer Modified Bituminous (PMB) coating provides excellent environmental, chemical and mechanical properties.

- Its unique feature ensures minimum thermal exposure to PET fibre, hence preventing polymer degradation and enhancing performance results like low elongation.

- Available in strengths ranging upto 800 kN/m and a width of 5.7 m

- Strata process ensures superior quality, consistency and dimensional stability

- StrataGrid is ISO 9001-2008 certified.

2. Biaxial geogrids- Biaxial geogrids like StrataGrid™ Biaxial (SGB) from Strata Geosystems are adaptable materials with similar strength in both directions. They are therefore perfect for managing pressures from different perspectives. Applications for them include slope protection, wall reinforcement, embankment support, subgrade reinforcement, soil stabilization, and foundation reinforcement. These geogrids stop soil erosion and increase the durability of the subgrade. They can be customized in width, length, and aperture measurements to meet the needs of a given project.

What makes StrataGrid™ Biaxial (SGB) differ from other biaxial geogrids?

The specialties of StrataGrid Biaxial SGB are as follows:

- Exceptional tensile resistance at lower elongations, surpassing conventional solutions in the market.

- Available in strengths ranging from 20kN/m to 150kN/m and a width of 5m, providing superior reinforcement for pavement base layers.

- Reduces pavement crust thickness, leading to faster and more efficient construction processes.

- Enhances structural integrity, mitigates settlement issues, and prevents soil failure, providing a solid foundation for embankments.

- Contributes to sustainability efforts by decreasing the carbon footprint associated with pavement construction.

Types of Geogrids based on manufacturing:

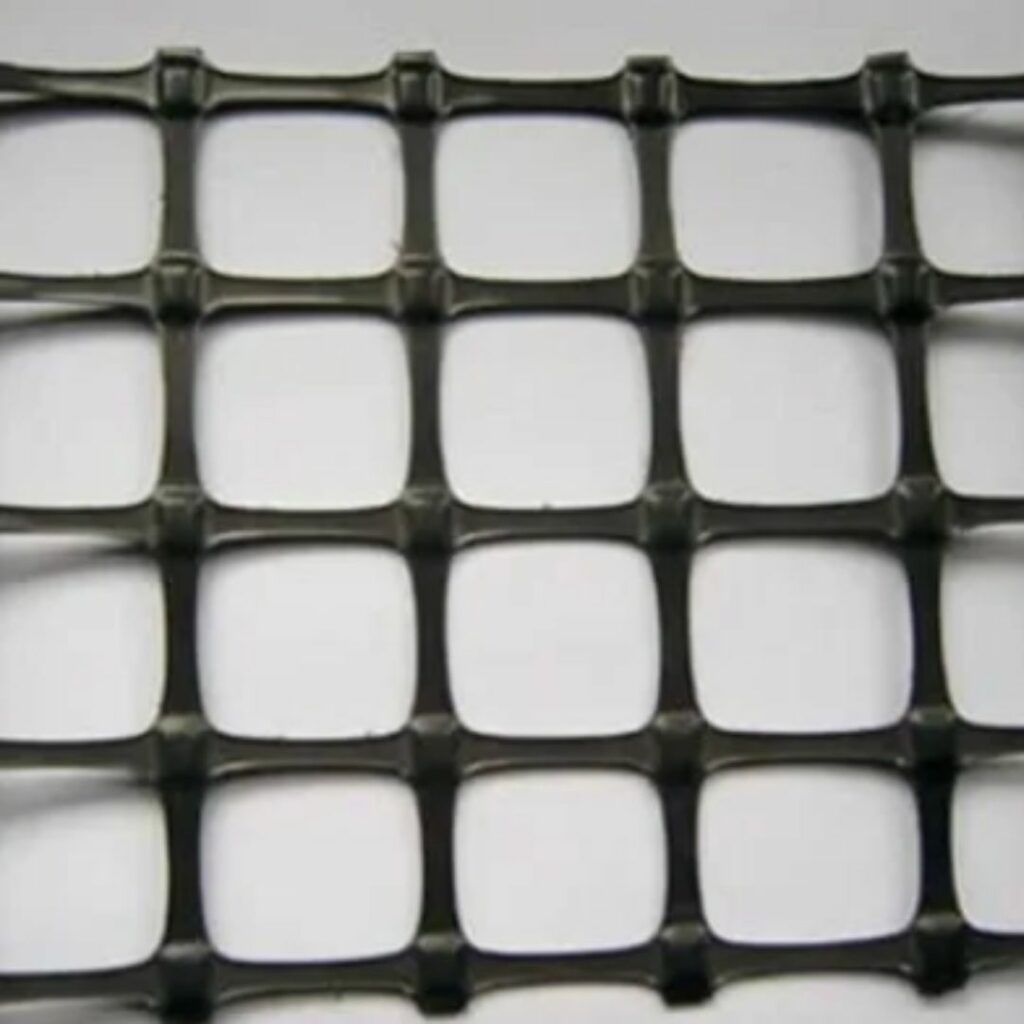

1. Extruded Geogrids- Extruded geogrids are made by stretching a thin sheet of polypropylene, resulting in a material with high strength and stiffness in the stretched direction. They vary in strength and stiffness based on the size and shape of their openings and ribs. Geogrids create a strong base layer that distributes weight evenly, reducing stresses and improving load-bearing capacity. Their rigid ribs and thick walls locked in aggregate materials, increases the resistance to sliding and movement. Extruded geogrids are available in uniaxial or biaxial forms, and they are used for railway trackbed stabilisation, basal reinforcement of embankments, bridge and railway abutments, retaining walls, reinforced soil slopes, reinforced foundation over piles, and reinforcement of granular road base and sub-base.

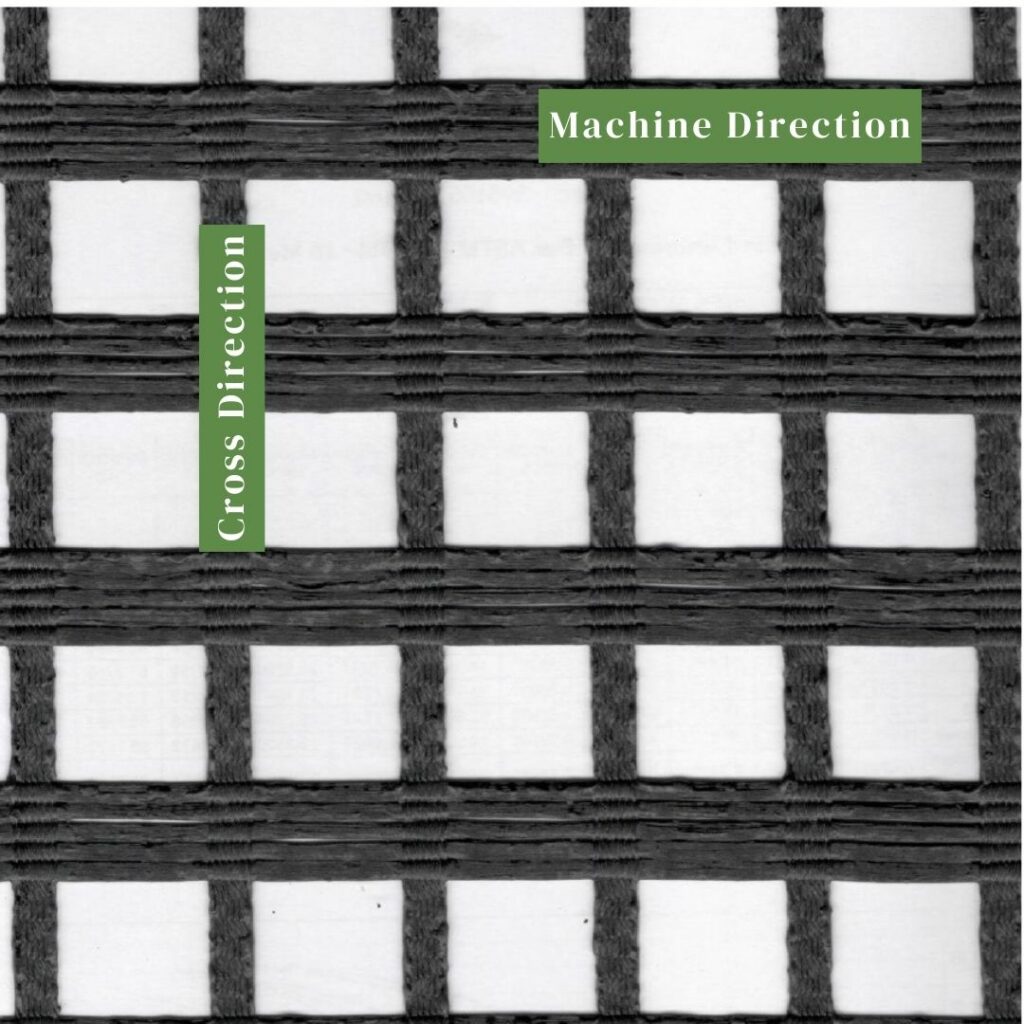

2. Woven geogrids- Woven geogrids are manufactured by weaving together polypropylene coated polyester fibres into longitudinal and transverse ribs and joining the crossovers by nodes. These geogrids are clothlike, with visible threads woven in horizontal and vertical directions, making them ideal for projects related to drainage, soil reinforcement, and erosion control. They are used to enhance subgrade conditions and minimise the quantity of aggregate. Woven geogrids are commonly made of polymer materials such as polyester, polyvinyl alcohol, polyethylene, or polypropylene. They are used as an alternative to traditional geogrids and have various applications in civil engineering and construction projects.

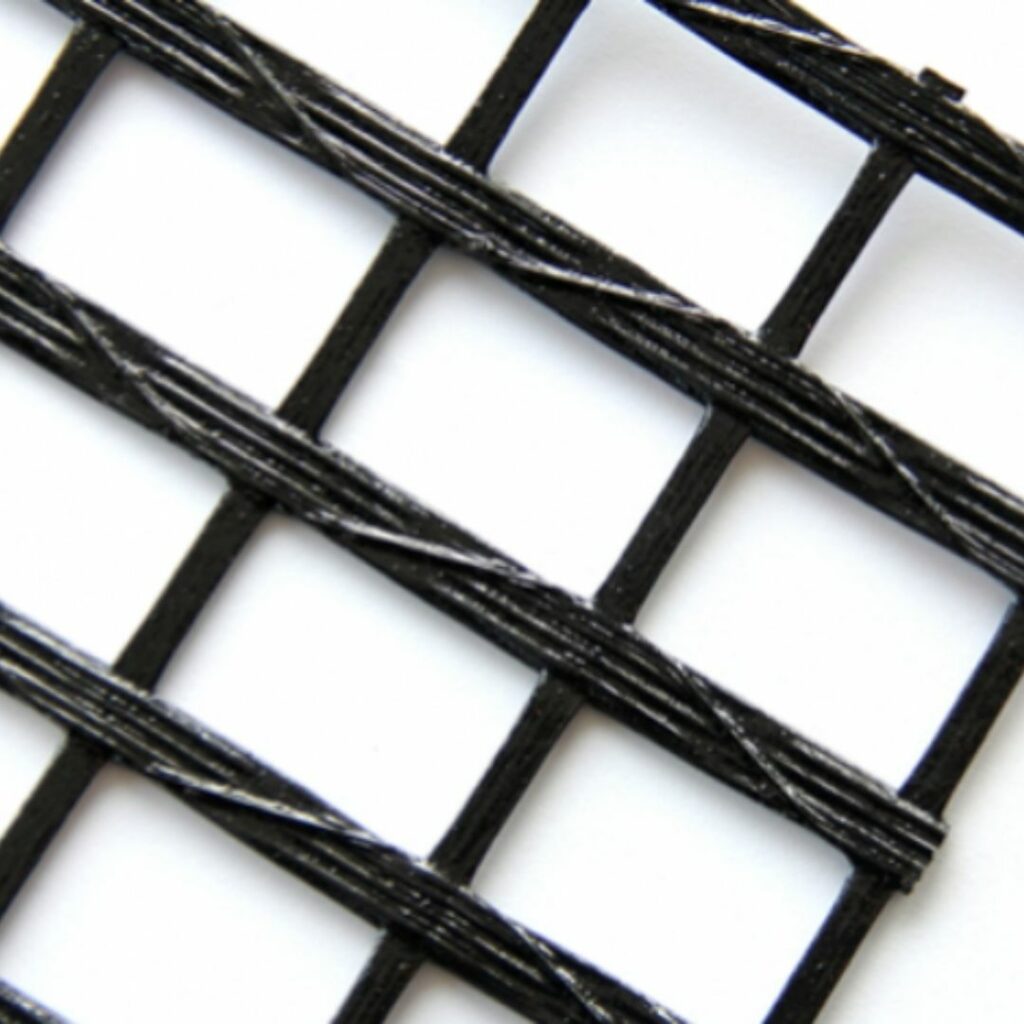

3. Bonded Geogrids- Bonded geogrids are made by joining two or more sets of strands or other elements at right angles and are coated with plastic. They’re like a grid or net with threads running both horizontally and vertically. These geogrids play an essential role in modern geotechnics and construction. They stabilize soft or unstable substrates and reinforce the subgrade, improving load distribution and increasing the soil’s load-bearing capacity.

Knowing the different types of geogrids is crucial for tackling soil stabilisation and reinforcement tasks effectively. From traditional woven and knitted variants to innovative geocomposites and eco-friendly options, each type offers distinct advantages. Strata Geosystems provides reliable results for soil stabilisation, earth retention, and soil erosion control projects occupying geotextile and geogrids, earth anchors, walls and slopes, turf reinforcement, revegetation, containment, and more. At Strata Geosystems, we specialize in guiding you through this selection process, ensuring that you find the ideal geogrid solution tailored to your project’s requirements. With our expertise in manufacturing top-quality geogrids since 2004, backed by cutting-edge technology and a commitment to sustainability, we empower you to achieve superior performance and longevity in civil engineering projects. Trust Strata Geosystems to be your partner in building a stronger, more resilient future.