This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Evolution of geosynthetics in civil engineering

How were geosynthetics invented?

Geosynthetics, an innovation in civil engineering, have significantly transformed civil engineering practices and infrastructure development. Belonging to a class of polymers, this category of products has numerous uses across a wide range of industries. Among the most common is its use in soil stabilization –a practice that has ancient origins, and has led to growth of human dwellings.

In the past, foundation engineers had limited choices for constructing projects on problematic soil textures. These included avoiding the site location entirely, excavating and replacing the soil with high-quality material, or designing the foundation based on the existing soil conditions, using reinforcements available at the time.

With industrialisation and evolution of materials, geosynthetics is a forerunner in soil stabilization techniques. This newer approach in building material designed to address specific industrial and civil engineering challenges. Geosynthetics are recognized for providing cost-effective, technically proficient, and ecologically sustainable solutions to complex engineering scenarios.

Sturdy, sophisticated, and with industry specific products, geosynthetics have been around for over sixty years. This comprehensive exploration dives into the history, types, and multifaceted functions of geosynthetics in civil engineering, highlighting their uses in enhancing the durability, stability, and sustainability of structures.

Evolution of geosynthetics:

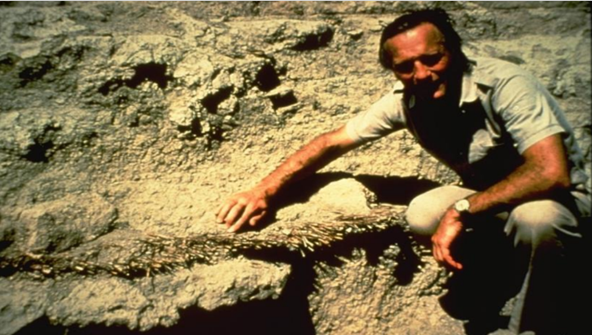

The earliest attempts at soil stabilization involved natural materials such as tree trunks, bamboo, and stones, with a history spanning over two millennia. The roots of geosynthetics can be traced to the 1920s in the United States when textiles were first utilized in road construction. The more modern concept of geosynthetics began to take shape in the late 1950s and early 1960s with the development of filter fabrics and geotextiles. Over subsequent decades, advancements in quality, variety, and manufacturing processes propelled geosynthetics into a prominent position within the field of civil engineering.

Geosynthetics- filtered, man made fabrics created in 1957. The credit of birthing an entire industry is often assigned to Dr. Robert M. Koerner – who with his lifelong love for geotechnical/geosynthetics engineering that spanned five decades – authored numerous books, papers, and taught many students. Monumentally, it was after authoring a book on fabric and liners, in 1980, his ideas spread. He is often referred to as the pioneer of geosynthetics. But, it was in 1977, that Jean-Pierre Giroud presented a paper in Paris, France, at a conference, coining the names “geotextiles” and “geomembranes” in the context of civil engineering.

Predating their works is the man known as the “father of soil mechanics” – Karl Terzaghi: an Austrian civil engineer, credited with the founding of “soil mechanics”. It was his investigations on the mechanics of soil that led to the field that is today largely known as geotechnical engineering. Terzaghi’s work came about just after the first World War I, stemming from his own experiences and challenges. Terzaghi’s research aimed to consolidate the existing findings on foundations, earth pressure, and slope stability and establish a cohesive set of principles The results of his research were published in his seminal work, Erdbaumechanik (1925); followed by Introduction to Soil Mechanics, in 1943–44.

Over the last three decades, the evolution of geosynthetics has been in the realm of materials, design, performance, and sustainability leading to a much wider acceptance and even deeper application in industry.

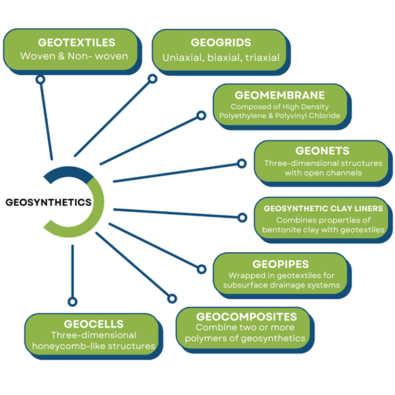

What are the common types of geosynthetics?

Geosynthetics refer to a wide class of materials, tailored to address many industrial needs, essentially aimed at reinforcement of soil. Some of the most common types of geosynthetics include:

1. Geogrids:

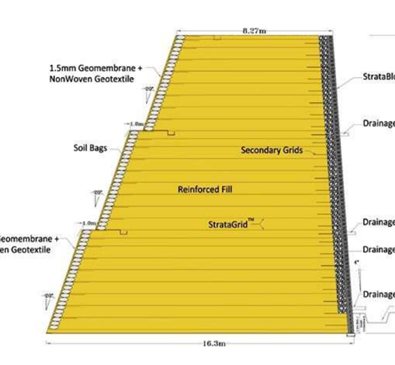

Geogrids serve as a reinforcement mechanism for soil structures. Their grid-like pattern distributes loads efficiently, preventing soil movement and enhancing the stability of retaining walls. These structures find applications in various civil engineering projects, from reinforcing slopes to supporting bridge abutments. Their shape is dependent on the type of geogrid –uniaxial, biaxial, or triaxial based on the directions it extends in.

2. Geomembranes:

Composed of impermeable materials like High Density Polyethylene (HDPE) or Polyvinyl Chloride (PVC), applications in environmental, hydraulic, transportation, and oil and gas applications, and waste management. In solid waste landfill projects, geomembranes prevent leachate, also known as, hazardous waste from contaminating the surrounding soil and groundwater. Their versatility extends to a wide list of applications such as fish pond lining, canal lining, transport of hazardous materials, lining highways to prevent hazards, ensuring containment and environmental protection. Depending on the area being contained the thickness of this membrane varies.

3.Geonets:

Geonets are three-dimensional structures with open channels that excel in drainage purpose. Their design allows for efficient water flow, reducing hydrostatic pressure in soil. Geonets are commonly utilized in subsurface drainage systems, promoting optimal drainage conditions in areas prone to excess moisture.

4. Geosynthetic Clay Liners (GCLs):

Geosynthetic Clay Liners (GCLs) find extensive use in landfill liners, mines, and mineral processing sites, offering an impermeable barrier that prevents contaminant migration. Their composite nature enhances both containment and stability in various environmental engineering applications. These prefabricated clay liners consist of sodium-bentonite (Na-B) sandwiched between two layers of geotextile, blending the sealing capabilities of bentonite clay with the reinforcing strength of geotextiles. GCLs serve as an alternative to traditional compacted clay liners, which are susceptible to weather and temperature changes.

5. Geopipes:

Geopipes play a critical role in subsurface drainage systems, wrapped in geotextile fabric. The geotextile wrapping ensures efficient water drainage by preventing soil particles from clogging the perforations. Geopipes are essential in managing groundwater levels and preventing water-related damage in civil engineering projects.

6. Geofoam:

Geofoam, a lightweight and rigid material, serves as an innovative solution for soil stabilization. Its low weight makes it ideal for slope reinforcement and embankment projects, reducing the load on underlying soil. Additionally, Geofoam’s insulating properties find applications in infrastructure projects where controlling soil freezing and thawing is necessary.

7. Geocomposites:

The term geocomposite generally refers to products that combine two or more polymer structures from the family of geosynthetics. The common configuration includes four classes: geogrids, geonets, geotextiles, and geomembranes, which can be used to essentially address separation, filtration, drainage, and soil reinforcement. Geocomposites are usually fabricated to address very specific engineering problems. This could be a pairing of geonet bonded with geotextile layer(s) on one or both sides. For example, geotextile-geogrid composites offer both separation and reinforcement properties, making them invaluable in road construction.

8. Geocells:

Geocells, three-dimensional honeycomb-like structures, provide effective soil stabilization and erosion control. Filled with soil or aggregate, geocells create a stable foundation for roadways and prevent soil erosion on slopes. Their modular nature allows for easy installation and adaptability to various terrain conditions. They help create a green facia where needed for slopes for a more aesthetic result in cons geomembranes are principally manufactured from polyethylene. They are barriers against liquid and gas migration. Its most typical application is to contain hazardous materials. As a result, this particular class of geosynthetic finds.

What are the key functions of geosynthetics in civil engineering?

Geosynthetics have applications across construction, landfills, mining, urban roads, highways and environmental projects to name a few. However, their uses are categorized in eight broad categories. The meta outcome from the use of geosynthetics is to bring stability to the ground, and overall structure for construction. Its eight primary functions are:

1. Reinforcement:

Geosynthetics, particularly geogrids and geotextiles, play a pivotal role in reinforcing soils and structures. By distributing loads more effectively, they enhance the overall stability of foundations and embankments. This solution is crucial in areas with weak or compromised soil, providing an economically viable solution to improve the load-bearing capacity of the ground.

2.Separation:

Geosynthetics vital function is to prevent the mixing of dissimilar soil layers. To maintain the integrity of different materials and prevent the deterioration of structural elements, geosynthetics like geotextiles act as a barrier. This feature of the material ensures long-term stability and performance by isolating incompatible materials, thereby mitigating potential issues arising from intermixing.

3. Filtration:

Geotextiles are commonly deployed for their filtration capabilities. They allow water to pass through while effectively trapping impurities and preventing them from migrating through the soil. This role is particularly valuable in drainage systems and environmental engineering projects where water quality is a critical consideration. By improving water filtration, geosynthetics contribute to the overall environmental sustainability of civil engineering structures.

4. Containment:

Geomembranes, a type of geosynthetic, are impermeable barriers extensively used for containment purposes. Landfills and wastewater treatment facilities rely on geomembranes to prevent the leakage of harmful substances into the surrounding environment. The containment function ensures the safety of both the structure and the surrounding ecosystem, emphasizing the crucial role of geosynthetics in environmental protection.

5. Drainage:

Geosynthetics, including geonets and geopipes, are employed to enhance drainage in civil engineering projects. Efficient drainage systems are essential to prevent water accumulation, which can lead to instability, erosion, and other structural issues. By facilitating proper drainage, geosynthetics contribute to the longevity and performance of various structures, from roads and embankments to retaining walls.

6. Barrier creation:

The use of geosynthetics as barriers is exemplified in retaining walls and flood protection systems. Geotextiles and geomembranes act as barriers against water infiltration, providing structural integrity and preventing soil erosion. This function is particularly critical in areas prone to flooding, where the proper design and implementation of geosynthetic barriers can safeguard infrastructure and mitigate the impact of natural disasters.

7. Erosion control:

In sloped terrains and embankments, geosynthetics play a vital role in erosion control. Geotextiles and geocells help stabilize soil, preventing erosion caused by rainfall, wind, or other environmental factors. The erosion control function ensures the long-term stability and safety of structures built on slopes, reducing the maintenance and repair costs associated with soil degradation.

8. Protection:

Geosynthetics are instrumental in protecting other materials during installation and operation. For instance, geotextiles can be used to shield geomembranes and pipelines from damage caused by sharp objects or rough surfaces. This protective function extends the lifespan of vulnerable materials, enhancing the overall durability and reliability of civil engineering projects.

The evolution of geosynthetics has positively influenced civil engineering, offering versatile solutions. For most of human evolution, settlements would be determined based on soil condition. With this technology, geosynthetics allow soil conservation and protection in the simplest form. From soil reinforcement and separation to filtration, containment, and erosion control, geosynthetics have become indispensable in modern construction practices. As technology advances, the development of new materials and innovative applications continues to expand the capabilities of geosynthetics, further contributing to the sustainability, resilience, and cost-effectiveness of civil engineering projects worldwide. The journey of geosynthetics from ancient soil stabilization practices to cutting-edge engineering solutions showcases their enduring relevance and vital role in shaping the future of infrastructure development.