This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

How geosynthetics are maximizing landfill airspace through vertically expansion?

Landfill expansions became a necessity, going as far back in the 1980s with it also being referred to as “piggyback landfill”. With the ever growing population, the need to identify or maximize sites containing waste was a necessity. This has become an even greater need today –with growing populations, expanding city limits and a paucity of space which can be used for refuse. Consequently, more than ever before, using a landfill space to the maximum capacity is the need of the hour. To this end, landfill expansion can be classified in 3 ways –horizontal expansion, vertical expansion and a mixed or hybrid approach. Each site demands a specific treatment based on the age of the debris, or waste, type of waste contained, height of the landfill itself, and water content present in the site. In this blog, we focus on vertical landfill expansion and the ways in which we expand an available landfill space. It’s worth noting that piggyback landfill refers to the method of adding more waste on type of an existing site, or cell, whereas vertical landfill deals with the idea of adding more height and claiming more airspace for expansion of the site.

What is vertical landfill expansion?

Vertical landfill expansion refers to the practice of extending the height of existing landfill sites rather than expanding their footprint, thereby increasing their capacity without requiring additional land. This method is particularly valuable in densely populated or land-scarce regions where horizontal space is limited and acquiring new land is impractical or costly. By optimizing the use of existing landfill airspace—the volume of space on a landfill site permitted for the disposal of municipal solid waste (MSW)—vertical expansion helps to maximize the efficiency of waste management operations, prolong the operational lifespan of landfill sites, and reduce the need for new landfill development.

How vertical airspace management for landfill works?

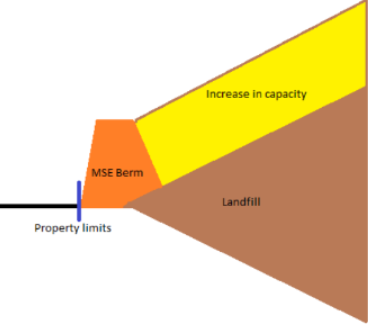

We simplify the process by adding a MSE berm in many instances around the landfill site. With this embankment in place, we can improve the volume recovery and build slopes with steep inclines of 70 degrees or more. As a result, it also offsets construction costs and maximizes airspace utilization, without the need for new approvals per se. We work with the existing design of the site. This is also more economical than constructing a new cell on the same landfill site.

Types of airspace management

While there are different types of airspace management techniques, within the purview of civil engineering we focus on perimeter retaining wall, landfill mining, or Mechanically Stabilized Earth (MSE) Perimeter Berm. In the case of MSE Perimeter Berms, we often employ this technique when lateral expansion is not possible for a given site. Embankments used for landfills typically have very flat slide slopes (1V:4H) occupying a larger land footprint. Strata’s steep slope solutions using StrataGrid™ are used effectively and safely to maximize land use for such embankments by allowing higher utilization of airspace in a smaller land footprint. Strata MSE berms have been used for vertically expanding an existing landfill, which requires lesser approvals and saves on costs while providing extra storage capacity. Though there are other ways such as waste compaction, shredding and other methods –we will limit the purview of this blog to civil engineering focused techniques.

Role of geosynthetics in landfills

Geosynthetics are the unsung heroes of landfill engineering, always working in the background to ensure the safety, stability, and efficiency of the waste containment systems. These versatile products uniquely performs specialized function for serving another significant purpose in the landfill ecosystem. Knowing how far down the line we have come with new waste management technologies, the role of geosynthetics will help secure environmental soundness and robust structural stability for landfills. Understanding the special benefits that geosynthetics bring and using that understanding, we can help further enhance landfill design and performance for protection of the environment in which we live and for future generations.

Key components and benefits

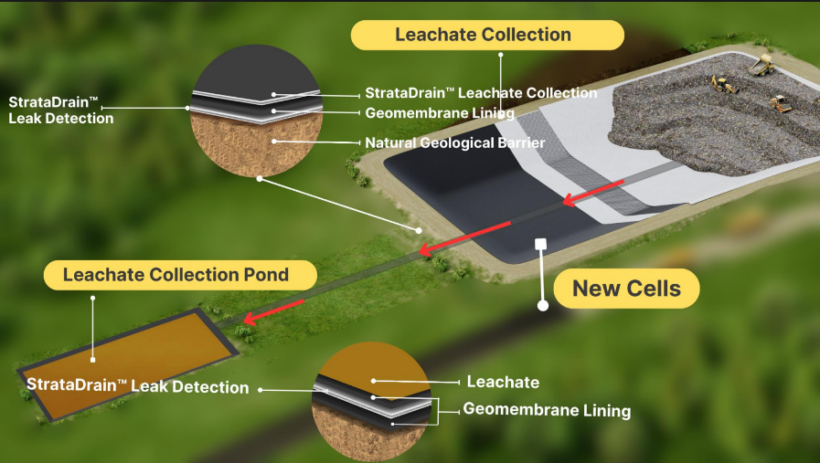

Geosynthetics include a range of products such as geotextiles, geomembranes, geogrids, geonets, and geocomposites. Each serves a specific function, from separation and filtration to reinforcement and gas collection.

Why geosynthetics are used in vertical landfills?

Vertical landfill expansions often face several challenges, with settlement issues being one of the primary concerns as waste accumulates weight and load. Geosynthetics play a crucial role in addressing these challenges and enhancing the overall performance of expanded landfills.

1. Stability enhancement:

Geosynthetics play a significant role in improving the stability of expanded landfills, ensuring that the increased height does not compromise the integrity of the structure.

2. Erosion control:

Preventing erosion is critical in vertical expansions. Geosynthetics protect the landfill cap and slopes from erosion caused by wind and water.

3. Containment efficiency:

Geosynthetics enhance the containment efficiency of landfills, securely isolating waste materials and associated byproducts from the surrounding environment.

Design and application of vertical landfill expansion process

Storing waste over older waste can reactivate settlement, depending on the type of the landfill expansion. This in turn leads to deformations in mineral and synthetic barriers if proper reinforcement structures are not in place. Therefore, design becomes a key element when accounting for expansion of an existing site.

Design principles

When using geosynthetics for vertical landfill expansion, there are a number of factors we must account for. Right from managing the existing volume, sedimentation, compaction, and space constraints, to ensuring the structural integrity of the new space is intact –there is a considerable amount of future and retrospective vision needed to ensure the new space is finally safe, cost-effective and achieves the objectives of providing more waste management space. Further, slope failures are a common and typical concern for landfills. It doesn’t help that space is often the most expensive commodity without getting into concerns of complex regulatory requirements for approvals.

Basic design considerations for vertical landfill expansion

Unlike the traditional earth embankment with a trapezoidal cross-section, the structure of reinforced soil structures is slim, occupying a land footprint only to the extent of its utility need, with very steep side-slopes. What’s more is that compared to a reinforced concrete or structural steel system, its cost is a mere fraction in comparison. This is a key consideration because space is at a premium and structural stability cannot be achieved easily. The features for landfill contaminants include applications of reinforced soil technology and an out-of-the-box concept for greening steep embankment slopes shrouded with untextured geomembrane.

The idea of reinforced soil containment for landfills arose from the landfill at Donzi, Atlanta in Georgia, USA. Here, necessity drove innovation by Strata US. The main issue was lack of space that necessitated vertical expansion of the landfill. The success of this idea in the US was a cue for Strata Global to hone this innovation further, using our geogrids and StrataSlope system for geogrid reinforced steep slopes with wire basket fascia. As was the case with the Donzi landfill and Vapi, India not all landfills are quite the same. The slope steepness is also a key factor in how the design of the vertical expansion plays out.

Case studies and examples of successful projects

Case studies of successful vertical landfill expansions provide valuable insights into the practical application of geosynthetics. They highlight innovative solutions to complex challenges and demonstrate the benefits of these materials in real-world scenarios. Let’s consider case studies of Strata Global involved in vertical expansion of landfill.

1. Strata Global built India’s first vertical landfill: A historic landmark-

The Vapi Green Enviro Limited landfill cells ran out of space to take in the increasing waste being produced by industries in the area, posing a very pressing problem. Due to the availability of less space and cost concerns, horizontal expansion was not feasible. Strata Global brought a revolutionary solution to the tableᅳvertical expansion of the landfillᅳchanging the game. Three major challenges were faced during the landfill construction:

High 14m landfill wall with a steep 70° inner slope in the design that requires innovative reinforced soil slope solutions. We utilized a reinforced soil structure with precast concrete modular block fascia and composite lining for maximizing the landfill capacity with the utmost regard to safety. Vertical expansion over existing embankments in some parts of the landfill; strengthening the existing embankment with soil nails to support the new reinforced soil walls. Greening steep slopes of the landfill that is covered with untextured geomembrane. We tackled this by the use of StrataWeb® geocells supported by StrataGrid™ geogrids for soil holding and vegetation growth for the slope as steep as 1V:1.5H.

In the construction, two major systems had to be implemented: StrataSlope™ and StrataBlock™. The inner slope, which was reinforced with StrataGrid™ and wrapped around soil bags, prevented the landfill leachate from leaking out. Meanwhile, StrataBlock™, precast concrete modular blocks, provided a solid outer facade, giving it a fortress kind of appearance for the structure. In spite of the difficulties, Strata’s team delivered a landmark solution that served not only the pressing needs of Vapi Green Enviro Limited but also set the new standard for landfill design in India.

2. Vertical Expansion of ACUA Landfill Using Strata’s MSE Berm Solution in Egg Harbor Township, NJ

In Egg Harbor Township, New Jersey, the Atlantic County Utilities Authority (ACUA) faced a pressing need to expand storage capacity at their solid waste landfill to accommodate waste for the next 20 years. Due to restrictions on lateral expansion caused by space limitations, costs, community objections, and environmental regulations, they required a vertical expansion. The existing containment berm, designed as a mechanically stabilized earth (MSE) wall, could not meet this need. Consequently, they decided to construct an additional MSE berm beyond the existing one, raising the landfill’s height.

They entrusted Wyndham Construction, LLC, with this complex project, which constituted Phase II of the landfill’s vertical expansion. Strata’s solution played a pivotal role in the project, using StrataGrid™ master rolls, black steel welded wire forms and struts, and a combination face wrap (SB1120 and permanent TRM). We deployed each StrataGrid™ roll, measuring 12.5 feet in width and 1,440 feet in length, through a spooling operation, ensuring minimal waste and reduced time and costs.

The Strata MSE berm’s key advantage lies in our ability to enhance landfill capacity without expanding its footprint. StrataGrid™ wrap and wire form facing contribute to the structure’s flexibility, preventing issues from differential settlement. We used reinforced backfill material, specifically Reclaimed Asphaltic Pavement (RAP), after extensive testing at a third-party laboratory confirmed its suitability. This method of expansion not only proved cost-effective but also swift, aligning with the project’s aggressive construction schedule and the need for a well-planned execution. Overall, Strata’s innovative MSE solution provided a robust and efficient method for ACUA to meet their future waste storage needs, demonstrating significant advantages in both construction speed and cost management.

Key learnings and innovative approaches of Strata Global

With land being a limited resource, our projects in landfill design are always at the intersection of technology, problem solving and sustainability. The most important lesson from vertical landfill expansion case studies is the effectiveness and efficiency in using innovation to solve space constraints. The two projects show that the use of vertical expansion techniques to maximize the landfill capacity within a space-constrained area is quite feasible and successful.

These projects have illustrated how dumping capacity can be increased by using reinforced soil structures and special engineering solutions, such as steepened slopes and specific reinforcement systems, subject to height and infrastructure limitations. The success of these projects reflects the potential of similar vertical expansion strategies for new standards in landfill design and inspiration for similar projects elsewhere in the world with innovative approaches for landfill engineering.

Our team at Strata Global makes a difference to communities, and governments by staying ahead of the curve in the technology for vertical landfill expansion and impacting the need to change the dimension of waste management and environmental protection. We have engineered products like StrataGrid, StrataSlope, StrataWeb, StrataTex HSR and more for providing sustainable and durable landfill expansion solutions. By using our cutting edge geosynthetic products we stay ahead of the curve in landfill technology, making a real impact on waste management and environmental protection. Investment in continuous training and education initiatives furthers the empowerment of our teams to act with best practices to drive positive change in waste management and environmental sustainability.