This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

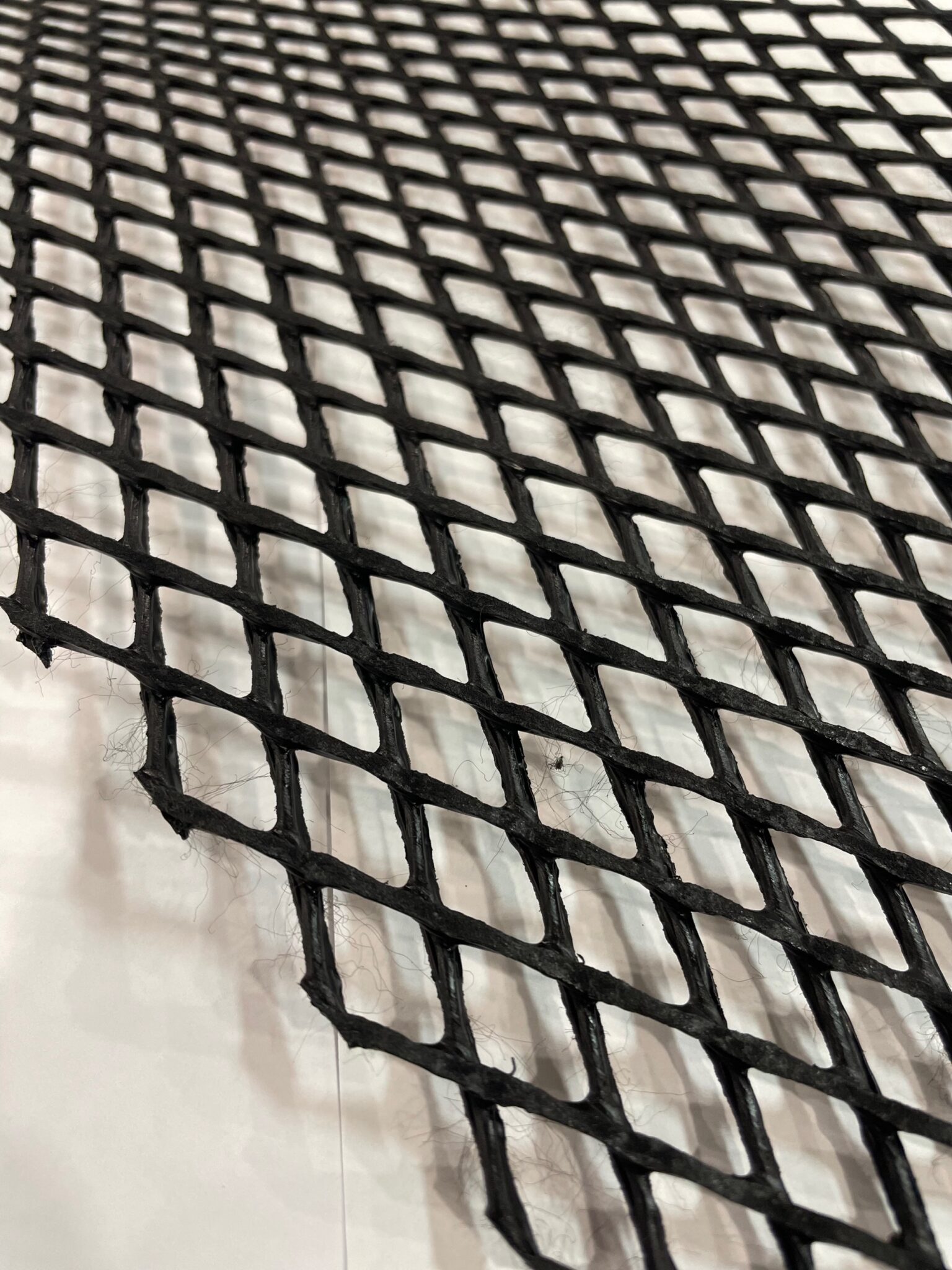

Biplanar net

Biplanar drainage nets are a geosynthetic material in the field of civil engineering used to improve water management projects, slope stabilization and green roof systems. These innovative nets are designed to curtail erosion and ensure stability in geotechnical projects because of their unique structure, which facilitates efficient soil reinforcing and water drainage.

What are geonets?

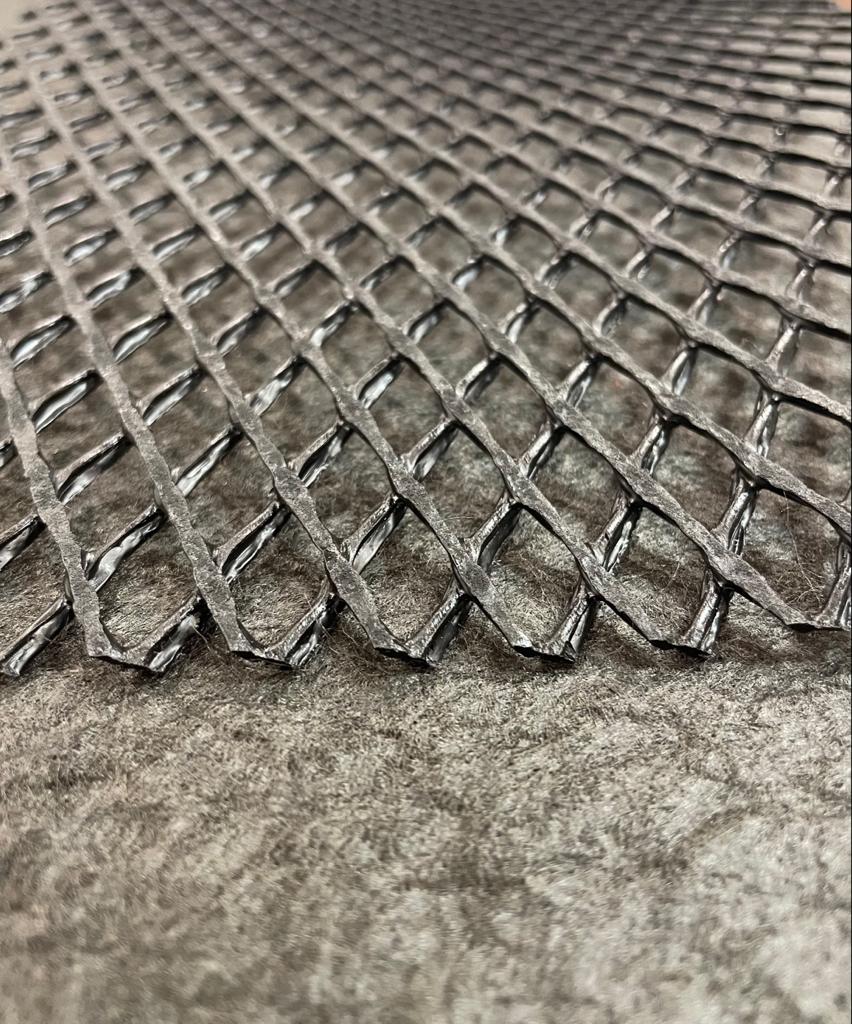

Geonets are advanced geosynthetic materials made primarily from high density polyethylene (HDPE) or polypropylene. They are arranged with a grid-like structure consisting of ribs or channels that create a three- dimensional network.They are primarily employed for drainage, retaining walls, asphalt work, dams, landfill liners and other geotechnical applications as they enable surplus water to flow through their mesh-like material. Typically, they’re a part of drainage systems to design and direct the flow of liquids – be it water or chemicals. This unique structure supplies efficient in-plane drainage capabilities,by optimizing transmissivity, enabling them to effectively regulate water flow and other liquid materials. Geonets must exhibit robust creep resistance and compressive strength to endure long-term stress and pressure in engineering implementations.

Types of geonets

Geonets can be categorized into four types based on the structure, use and requirement of the various civil engineering projects.

- Bi-planar geonets: Bi planar geonets are the two dimensional structure consisting of two flat parallel layers crafted to allow water to flow in both horizontal and vertical directions. They are widely used to develop channels for drainage.

- Tri-planar geonets: Triplanar are the three-dimensional structures with two outer layers of ribs and one internal layer of cross ribs that merge them and are widely used to control high flow rates and provide additional stability.

- Polymeric geonets: Polymeric geonets are manufactured from single polymers and employed for landfill drainage and wall retention . These are widely opted for their durability, chemical resistance and lightweight properties.

- Composite geonets: Composite geonets are built by integrating polymeric geonets with geotextiles and widely used for drainage, soil separation and filtration. These are available in numerous thickness and width and regarded as strong and stable contrasted to other geonets.

Manufacturing process of geonets

The manufacturing process of geonets involves several steps. They are,

- Material selection: The process begins with selecting high quality polymers which are durable, chemical resistant and lightweight.

- Extrusion: During the process, raw materials are melted to form a sheet or film. This step is vital as it dictates the thickness and texture of the geosynthetics.

- Orientation: This involves stretching the material to elevate its strength and drainage proficiencies.

- Cooling: The cooling process ensures that the material retains its properties by typically using water or air cooling methods, depending on the prerequisites.

- Stabilisation: Stabilisation involves steps to enhance the geonet’s resistance to environmental factors, making them appropriate for stability even in rigid conditions.

- Punching and cutting: Geosynthetics are cut into specific dimensions according to the stipulation of projects like drainage in landfills, retaining walls etc.

What are biplanar drainage geonets?

Popularly known as biplanar nets, biplanar drainage geonets play a vital role in sustainable construction practices. These geonets deliver long service life because of their resistance to harsh UV rays, chemical exposure and environmental degradation. The energy efficiency afforded by biplanar nets is becoming more apparent, as the demand for durable infrastructure increases.

Due to their honeycomb cell structure, they render more surface area for water to flow through without clogging up the system and hence makes it appropriate for efficient drainage and soil stabilization.

Benefits of biplanar drainage geonets

- Cost effective: Compared to other drainage methods, biplanar nets require only less backfill material and hence, less maintenance and repair costs. The versatility and adaptability also contribute to cost-efficiency.

- Environmental protection: Biplanar nets play an essential role in stormwater management as geoents facilitate the movement of water and promote groundwater recharge. By stabilising soil, geonets protect against the loss of fertility and preserve natural habitats.

- Recyclability: Since it is made from HDPE, these geosynthetic materials are fully recyclable. Hence, it contributes to reducing plastic waste and conserving natural resources.

- Durability: Biplanar nets are resistant to chemicals and UV degradation as they are made from HDPE. This ensures a long service life which reduces the need of frequent maintenance.

- Lightweight: These are lightweight which makes them easy to handle and thereby quick and efficient installation, reducing labor requirements. They are also used as additional shielding for waterproofing membranes.

Applications of biplanar nets

Being a versatile geosynthetics, biplanar geonets are widely used in many applications. They are :

- Landfill drainage: Biplanar geonets play an indispensable role in preventing leachate drainage. Being a rib geometry, it allows divergent flow in all directions , reducing hydrostatic pressure ,hence averts groundwater contamination. They are widely utilised for flat drainage applications like the core of a landfill or a leachate pad in mining scenarios and thereby prevent the water build up.

- Slope stabilization: In geotechnical engineering, Biplanar nets are employed for embankments and retaining steep slopes and walls as they are utilised to regulate surface water runoff and alleviate the risk of landslides.They also provide additional tensile strength and reinforcement to the soil. These nets also amplify the stability and load bearing capacity of various infrastructures.

- Erosion control: Biplanar nets provide additional support to the soil and prevent soil particles from being washed away making way for erosion control. They also dispense a clear path for water to evade by reducing the buildup of hydrostatic pressure. They also foster vegetation growth by allowing water to reach plant roots.

- Green roof systems: Biplanar drainage geonets are splendid for use in green roof applications because of their capacity to efficiently regulate the water flow by preventing waterlogging and provide structural support to the roof’s soil and vegetation, thus contributing to energy efficiency and urban biodiversity.

Triplanar vs biplanar drainage geonets

Biplanar is composed of two plane layers that allow multidirectional water flow whereas triplanar is a three dimensional structure with two outer planar layers and one internal layer which provides more robust drainage capabilities. Triplanar is usually designed for high flow scenarios and steep slopes as they offer better drainage performance. Biplanar have low load bearing capacity and are subjected to easier installation, whereas triplanar is capable of greater loads making it suitable for high traffic areas and more complex designs may demand careful handling and installation techniques.Triplanar may be expensive due to its three dimensional designs.

Determining the right type depends on the specific drainage requirements, the gradient of the site, the overall load, drainage capacity and budget.

Limitations of biplanar geonets

There are some limitations and challenges associated with biplanar geonets. They are:

- Limited load bearing capacity: Biplanar nets may have lower load bearing capacity compared to other drainage solutions. This can be a concern in heavy traffic areas.

- Potential clogging: Sometimes, biplanar nets can cause clogging if not paired with appropriate geotextiles. This causes the abatement in efficiency over time.

- Environmental conditions: In harsh environmental conditions, these geonets may degrade faster impacting their long-term reliability.

Relation between geonets and geocomposites

Geocomposites are the geosynthetic materials that combine multiple geosynthetic layers like geotextile, geonet etc. Geonets are usually sandwiched between geotextiles which allows them to effectively manage waterflow making them suitable for landfill caps and liners, stormwater management, slope stabilization, roadway and embankment drainage. Thereby, geocomposites are crucial tools in modern civil engineering projects.

Biplanar nets being a versatile geosynthetic material provides a wide range of uses across civil engineering projects. They offer excellent drainage competencies for retaining walls and soil separation. By precluding soil clogging and allowing for rapid water flow, biplanar nets contribute significantly to structural stability and environmental protection. These nets will play a vital role in addressing the setbacks posed by urbanisation, climate change and environmental protection and by supporting ecological health and the future of these geonets look promising.